CONSTRUCTION OF THE 8X20 VERTICAL CAMERA

METAL WORK

As with the 4×10 camera project, this camera requires that all of the hardware be custom machined. All of the knobs and fittings are made from brass or aluminum round or flat stock. Since the 8×20 is a much larger camera, much of the hardware is constructed from aluminum. Brass is approximately three times denser than aluminum. So, every part made from aluminum is 1/3 the weight. The biggest problem with aluminum is it must be anodized. I had to learn to anodize in order to complete this project. About 95% of this camera has aluminum hardware. The other 5% is brass. All aluminum is gold anodized to match the brass.

As with the 4×10 camera project, this camera requires that all of the hardware be custom machined. All of the knobs and fittings are made from brass or aluminum round or flat stock. Since the 8×20 is a much larger camera, much of the hardware is constructed from aluminum. Brass is approximately three times denser than aluminum. So, every part made from aluminum is 1/3 the weight. The biggest problem with aluminum is it must be anodized. I had to learn to anodize in order to complete this project. About 95% of this camera has aluminum hardware. The other 5% is brass. All aluminum is gold anodized to match the brass.

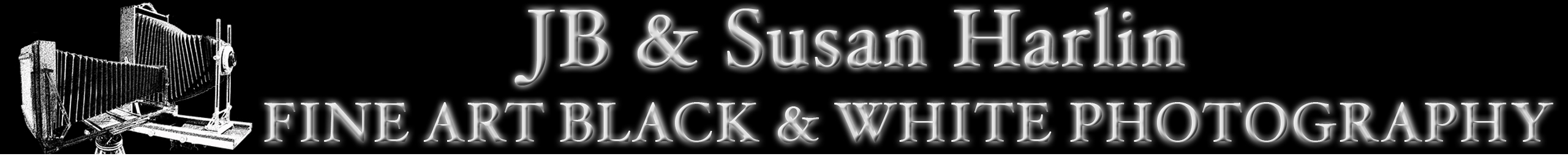

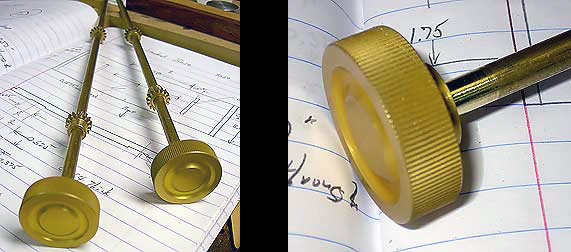

Knobs are formed on a lathe from raw aluminum round stock.

Each knob requires several steps to complete. Once it is machined to its final shape, its outer surface is knurled.

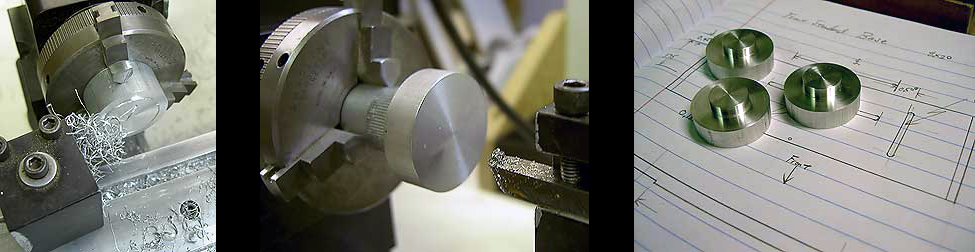

Some parts are fabricated from flat stock. Above a piece of flat aluminum is formed and then machined to make the front standard base.

In order to machine some pieces,it is necessary to make a fixture. Here the front standard uprights are being machined. Normally the holding fixture would be constructed from aluminum, but since this is a one-off design, hard wood was used. This fixture is used to make the two pieces and is then discarded.

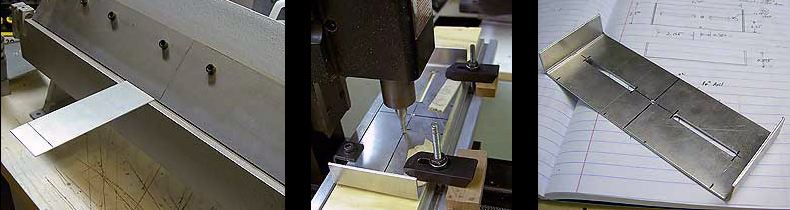

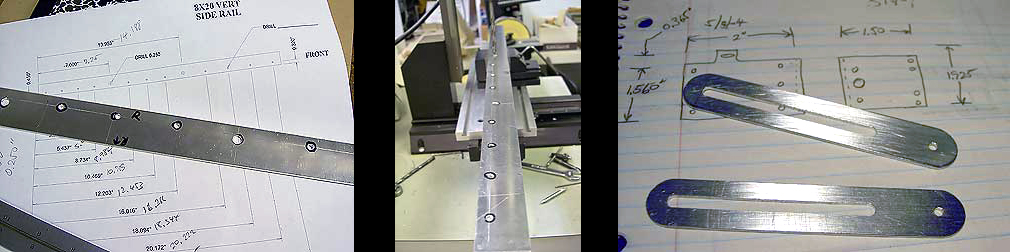

Some flat parts only require holes or slots be machined into them. Above the side rails for the base are shown along with the braces for the front standard.

Once all of the parts are complete, they are assembled to check for proper fit and function. Here is the front standard as it is assembled.

Here is the rear standard assembled.

The camera bed with front and rear standard assembled.

Once all of the aluminum parts are finished and checked for fit, they are buffed then chemically cleaned and placed into an anodizing solution. After anodizing the aluminum is then bathed in a gold dye, then chemically hardened.

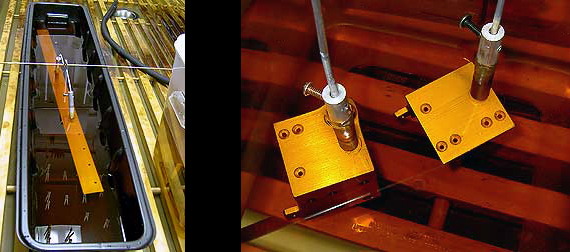

Above the side rail (left photo) requires a long tray for the process. On the right is the film back mounting brackets.

Here the main focus knobs have been installed on the drive shafts.

Here the main focus knobs have been installed on the drive shafts.