Over the years we have used numerous developer and other chemical formulas in the darkroom. After years of experimentation, with a lot of trial and error, we have now come to a point where we mix near everything from raw chemicals. There are certain advantages to mixing your own. You know the contents of everything you use and if there is a mistake, you know who to blame!

Mixing your own darkroom chemistry is not difficult. You do not need to be a chemist. If you can follow a recipe and bake a cake, you can mix your own chemistry. Do some research and experiment, you may just be surprised with your results and with a little knowledge you can alter a mixture to suit your vision.

Here on this page you will find the formulas that we use in the darkroom. Keep in mind, these are the formulas we use and they suit our vision and the way we work. If you are interested in mixing your own chemistry, here is a starting point. Should these formulas work for you, then great! If not, maybe you will learn something.

CAUTION: Keep in mind that these formulas contain chemicals that could be hazardous. Practice safe handling procedures when working with and mixing chemicals.

FILM DEVELOPER

PYROCAT HD FILM DEVELOPER

1 LTR STOCK ‘A’

Water (125ºF) ……………..…..………. 750 ml

Sodium Metabisulfite …………………. 10 g

Pyrocatechin ……………….………….. 50 g

Phenidone (*Note) …….….…………… 2 g

Potassium Bromide ………….………… 2 g

Water to make ……………..….……….. 1 liter (1,000 ml)

*Note: Mix 2.0 g of Phenidone with about 5 ml of Isopropyl Alcohol and stir into an even mixture, then add to the stock solution and stir till dissolved.

1 LTR STOCK ‘B’

Water (68ºF)……………………………. 750 ml

Potassium Carbonate………………… 750 g

Water to make………………..……….. 1 liter (1,000 ml)

NOTE: Use Distilled Water in all stock solutions.

We use PyroCat HD at a mixture of 2:2:100. That is 2 parts ‘A’ plus 2 parts ‘B’ plus 100 parts distilled water. Each type of film should be tested for proper EI and developing time.

PyroCat HD was formulated by Sandy King. For more information look HERE.

More good information here, “An Introduction to Pyro Staining Developers, With Special Attention to the Pyrocat-HD Formula” by Sandy King.

Want to learn more about pyro staining developers? We now offer an online video workshop that explores those traits that make pyro film developers unique. Follow this link to The Darkroom Workshop for more information.

PAPER DEVELOPER

PPPD-JBH Cold Tone Paper Developer

SOLUTION ‘A’

Water (125ºF) ……………..…..……… 750 ml …………….. 1,500 ml

Phenidone (*NOTE)………..…..……. 0.3 g …………………. 0.6 g

Sodium Sulfite ………………………… 43 g …………………. 86 g

Pyrocatechol ………………………….. 10 g …………………. 20 g

Citric Acid ……………………………… 5 g ………………..… 10 g

Potassium Bromide……..……………. 3.5 g ………….….….. 7 g

Water to make………………..……….. 1 liter …………….…. 2 liter

*Note: Dissolve in 5-8 ml of Isopropyl Alcohol then add to the stock solution and stir till dissolved.

SOLUTION ‘B’

Water (70-80ºF)……………………… 750 ml …………….….1,500 ml

Sodium Carbonate ………………….. 50 g ………………….. 100 g

Water to make………………..……….. 1 liter ………….…….. 2 liter

Mix 1:1 (1 part ‘A’ with 1 part ‘B’ to use)

This is our variation of the Pyro Plus Paper Developer (PPPD). This developer was originally formulated and published by Donald Miller. Our version is a cold tone developer and works well with Azo. For more information about PPPD and its various mixtures, search the Internet.

Also see this jbhphoto BLOG entry, “WHAT PAPER DEVELOPER ARE YOU USING THESE DAYS?“

PAPER DEVELOPER

THIS IS OUR REPLACEMENT FOR ZONE VI PAPER DEVELOPER

D-72

Water (125º F)………………..………… 750ml ………. 1500 ………. 2250 …………. 3000

Metol …………….………….……..……. 3 g ……….….. 6 g …….…… 9 g…….…….. 12 g

Sodium Sulfite ………………..……….. 45 g ……..……. 90 g …….. 135 g .……..… 180 g

Hydroquione ………..…….….……….. 12 g ………….. 24 g ……….. 36 g ……….…. 48 g

Sodium Carbonate …………..……….. 80 g ……..…. 160 g …..…. 240 g .………… 320 g

Potassium Bromide ….…..…….…..….. 2 g ……….….. 4 g …………. 6 g ……………. 8 g

Water to make ……………..…..………. 1 Ltr ………….. 2 Ltr ………. 3 Ltr …………. 4 Ltr

Mix 1:3 (One part Stock to three parts water.)

NOTE: Use Distilled Water in all stock solutions.

This is our replacement for the traditional Zone VI Print Developer. See this BLOG post for more information; ZONE VI; THE END

ACETIC ACID 28%

To make a 28% stock solution of Acetic Acid, mix 3 parts pure acid to 8 parts distilled water.

TO MIX A TOTAL VOLUME OF 28% ACETIC ACID TO FILL A 16 oz BOTTLE

Pure Acid ………………… 4.5 oz

Distilled Water…………… 12 oz

Total 28% mixture ……… 16.5 oz

NOTE: Always add acid to water. Never add water to acid.

STOP

Stop for PyroCat HD we mix 3ml of 28% acid to each 1,000ml of water.

Stop for printing paper we mix 40ml of 28% acid to each 1,000ml of water.

FIXER FOR FILM

Fixer for PyroCat HD we use Kodak Rapid Fixer, film dilution. Do Not add hardener (small bottle).

FIXER FOR PAPER

THIS IS OUR REPLACEMENT FOR ZONE VI PRINT & FILM FIXER

F-24 ACID FIXER FOR PAPER

Water (100-125º F)…………..………… 750ml ………. 1500 ………. 3000 …………. 6000

Sodium Thiosulfate ………….….……. 240 g ……….. 480 g ……… 960 g…….…… 1920 g

Pentahydrate **

Sodium Sulfite ………………..……….. 10 g …………. 20 g ……….. 40 g .……….… 80 g

Sodium Bisulfite ………….….……….. 25 g ………….. 50 g ……….. 100 g ……..…. 200 g

Water to make ………………..………. 1 Ltr ………….. 2 Ltr ………. 4 Ltr …………. 8 Ltr

**Sodium Thiosulfate Anhydrous 152 g 304 g 608 g 1216 g

*** CAUTION ****

Sodium Thiosulfate Anhydrous Water 80-85°F Never Over 90°F

Mix in the order shown and use undiluted. Fix paper for 4 minutes. Wash prints in running water for 5-10 minutes before second Plain Hypo fix. This wash is important, since this fix is acid and the Plain Hypo is alkaline. Transferring acid from the first fix will turn the second fix cloudy with a precipitate which will render the second fix useless. This is especially important if you plan to selenium tone. Any acid carried over into the toner will cause stains.

PLAIN HYPO

FOR SECOND FIX AND SELENIUM TONING

Water (100-125º F)…………..………… 750ml ………. 1500 ………. 3000 …….…. 6000

Sodium Thiosulfate ………….….……. 240 g ……….. 480 g ……… 960 g……….. 1920 g

Pentahydrate **

Sodium Sulfite ………………..……….. 30 g ………….. 60 g ………. 120 g …….… 240 g

Water to make ………………..……….. 1 Ltr ………….. 2 Ltr .……… 4 Ltr ……….. 8 Ltr

**Sodium Thiosulfate Anhydrous 152 g 304 g 608 g 1216 g

*** CAUTION ****

Sodium Thiosulfate Anhydrous Water 80-85°F Never Over 90°F

Plain Hypo is used as a second fixing bath. Use undiluted for 4 minutes. This may also be used before selenium toning since this fix is alkaline. Fix for 4 minutes, then directly into selenium toner until desired effect is achieved. Then place print in HCA ( see my formula below) and wash for 1 hour.

NOTE: If using Sodium Thiosulfate Anhydrous — To mix 1 Ltr use 152 g — To mix 2 Ltr use 304 g — To mix 4 Ltr use 608 g — To mix 8 Ltr use 1216 g

SELENIUM TONING

FOR PPPD-JBH DEVELOPED PAPER

1:20 DILUTION

Water (68-70º F) ……………. 32 oz …………………. 64 oz …………….……. 128 oz

Kodalk * ……………………… 0.125 tsp (1/8) ……… 0.50 tsp (1/2) …………. 1.00 tsp (1)

Selenium Toner…………….. 1.50 oz ……………….. 3.00 oz ………………… 6.00 oz

Toning is a very subjective practice and what works for one may not be acceptable to another. Selenium toner, and its effect on the finished print, is directly proportional to the strength of the toning solution and time. Also, the type of paper, and even the developer used, can change how the toner interacts with the finished image.

You need to experiment with what works for you. We have used dilutions from 1:20 to 1:80, depending on the results. Above is our current mixture which is 1:20. That is 1 part Kodak Rapid Selenium Toner to 20 parts water. The amount of Kodalk remains constant and is determined by the volume of water. You only vary the amount of toner stock solution.

*NOTE: Kodalk Balanced Alkali is Sodium Metaborate

PROCEDURE

1. Water in tray 5 min. (only if prints are dry)

2. Pure Hypo 3-4 min. (occasional agitation)

3. Kodak Rapid Selenium Toner diluted 1:20 to 1:80 2 to 6 min. (continuous agitation at 70-85°F)

4. Hypo Clearing Agent 3-4 min. (occasional agitation)

5. Wash

HYPO CLEARING AGENT

JBH HYPO CLEARING AGENT

Water (125º F)………….……..………… 750ml ……….. 1500 …….…. 2250 …….…. 3000

Sodium Sulfite ………………..………… 200 g ………… 400 g …..….. 600 g ………. 800 g

Sodium Bisulfite ……………………….. 1 g ……………. 2 g …………. 3 g ………….. 4 g

EDTA*……………………………………. 10 g ………….. 20 g ……….. 30 g ………… 40 g

Water to make ………………..……….. 1 Ltr ………….. 2 Ltr ………… 3 Ltr ……….. 4 Ltr

Dilute 1:9 for use

* EDTA is added to prevent hard water precipitant from forming during use and may be left out if not needed.

This is the HCA formula we have used for years. We do not use HCA with film, so this is used for fiber paper. Mix stock solution 1:9, that is one part stock to nine parts water. Shuffle paper in a tray of working solution for 3-4 minutes, then wash for one hour. NOTE: Test your washer, your wash time may be different.

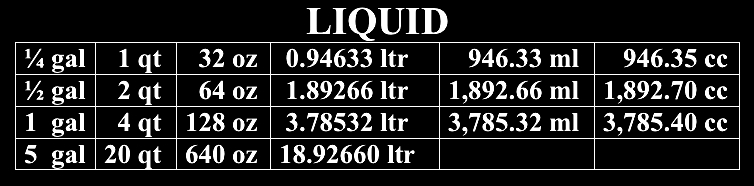

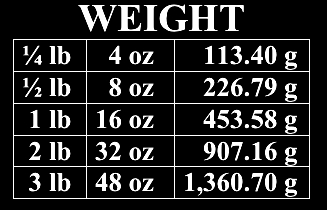

MEASURE

NOTES

- USE DISTILLED WATER FOR ALL STOCK SOLUTIONS

- WE USE DISTILLED WATER FOR ALL DILUTIONS OF CHEMICALS WHEN PROCESSING FILM. YOU ONLY GET ONE CHANCE HERE.

- PAPER STOP, FIX, AND HCA ARE MIXED WITH TAP WATER

- FILM AND PAPER ARE WASHED IN TAP WATER FOLLOWED BY A BRIEF RINSE IN DISTILLED WATER BEFORE DRYING

- FILM IS AIR DRIED USING WOODEN CLOTHESPINS ON AN OVERHEAD LINE

- PAPER IS AIR DRIED ON PLASTIC WINDOW SCREENS

- REMEMBER, THESE ARE THE MATERIALS WE USE. . . YOUR MILEAGE MAY VARY???

KEEPING PROPERTIES OF VARIOUS MIXTURES

- I have kept PyroCat HD in partially full dark amber bottles, tightly sealed for over a year without incident. Part ‘B’ should keep for years.

- Diluted acid (28%) will keep for years.

- Fixer is thrown out if not used in three months.

- Mixed selenium toner is the only chemical we keep and use over until it is exhausted, or has been mixed for three months.

- The house rule is, never dump anything back into the bottle after it has been used.