Fixer does not soon become “exhausted” in the sense that it can’t dissolve more silver salts. Instead, the trouble is with silver/sulphur complexes that build up as the hypo is used. They can’t be washed out of paper. One of Alfred Stieglitz’s sins was that in spite of excellent training in photographic sciences at the Berlin Technische Hochschule under the great Wilhelim Vogle (whose discoveries made orthochromatic and panchromatic film possible), Stieglitz told the young Ansel Adams that a gallon of fixer is good for thousands of prints. He thought that Kodak’s advice to change the hypo frequently was just corporate greed-anxiety to make big profits selling more dirt-cheap hypo. No doubt that’s why some Stieglitz prints are turning funny colors.*

* Photo Techniques Magazine, “Advanced B&W Printing” 2002, “Photo 303, The Pratt Institute Handouts” by David Vestal, p.40

Nothing lasts forever. And, this is even more true when it comes to photographic chemistry. The question is, how long does the chemistry used in the darkroom last once mixed and what is the exhaustion rate? I firmly believe that trying to milk photographic chemistry for every last little bit is a recipe for disaster. Think of it this way. You have invested a lot of time and money by the time you get into the darkroom. Is it really worth it to try and save a few dollars by pushing your luck with chemistry that may not be up to par? Honestly, the least expensive item you use in the photographic process is the chemistry and water. Why scrimp, and risk disaster?

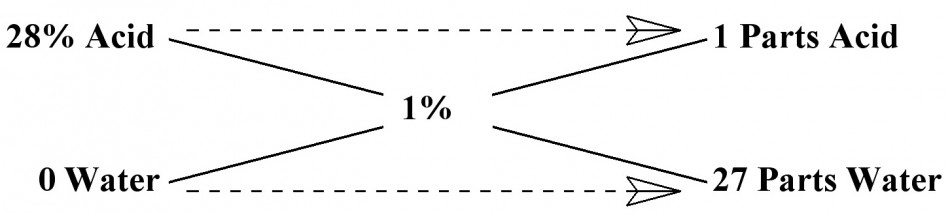

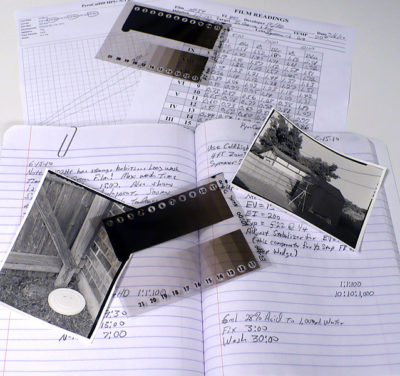

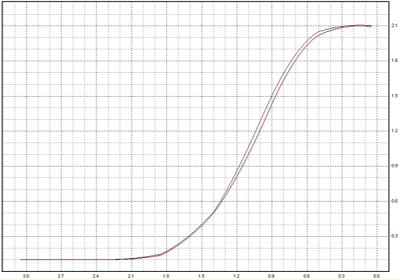

We calculate the exhaustion rates of all chemical formulas we use. It is very important to know the capacity of the film developers you use. If you try and stretch the chemistry beyond its useful capacity you will ruin your film. Same thing happens with the fixer. Printing paper is the same, except if you make a mistake you can always start over. But with film there is no do-over.

We very closely watch the capacities of the chemistry we use. The basic rule in our darkroom is to assure that we seldom go beyond 50-60% capacity. Film developers are used one-shot, making sure to use an adequate volume of chemistry for the number of square inches of film being developed. Film fixer is ran to 50-60% capacity then discarded. The same criteria is used when printing. Paper developer is used to maybe 60-70% capacity then discarded. Paper fixer is never used more than 60% of capacity.

In our darkroom there are few chemicals that are not discarded after a darkroom session. The only fixer we keep is the rapid fix used for film and it is discarded at 50-60% capacity. The only other chemistry we keep is Selenium Toner. All chemistry is labeled with the date it was mixed. Those that are kept for reuse are marked with the number of sheets of film or paper it has seen.

There is no need to run the risk and facing the consequences of exhausted chemistry when it comes to your photography. As said before, the chemistry is the least expensive item you will use in the whole photographic process, from film to the finished print. It is not worth the possible disaster that scrimping can cause. It is important to know the capacities of every formula used and never run any to full exhaustion. Nor is it a good practice to keep mixed solutions too long. Some formulas deteriorate rapidly once mixed. Know your chemistry and use it wisely!

JB

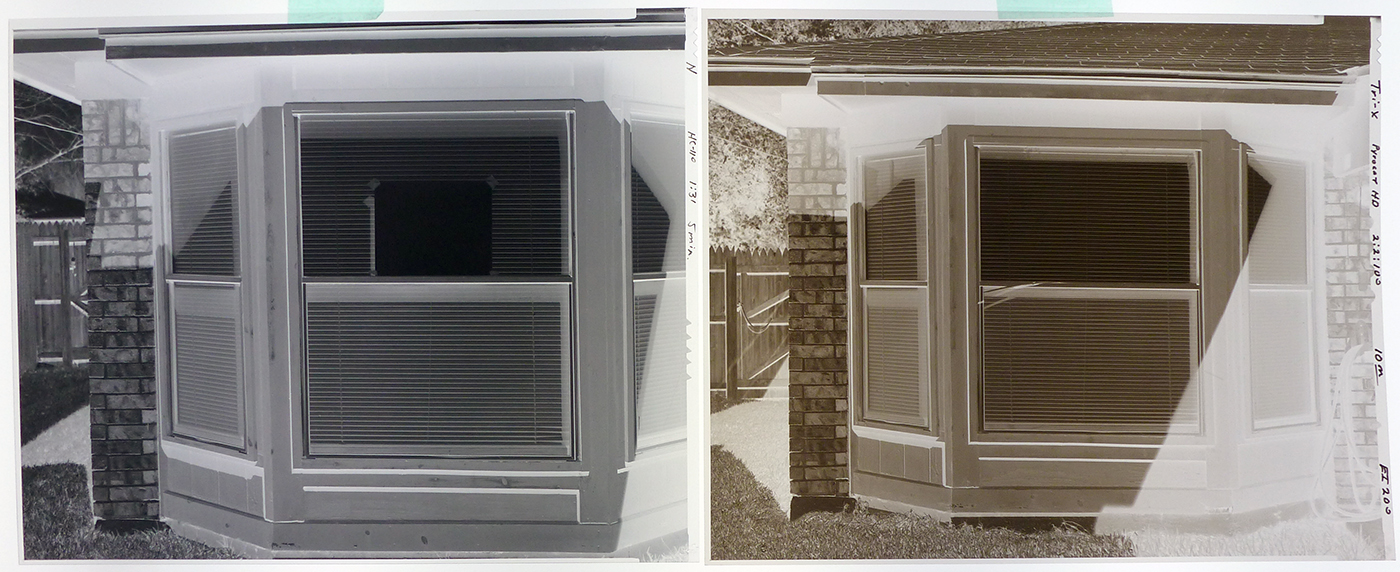

When we first started working with Pyro developers it took some time to realize exactly how the different look and feel of the film would translate into the finished print. There are those that say there is no difference between different film developers. They may also say there is no difference in the film you choose. That is like saying there is no difference between Ford and Chevy; no difference between red or white wine. Maybe for some this may be the case. But for those that take the time to really look and absorb the image, there is always a difference. Fred Picker said, “different is not the same!”

When we first started working with Pyro developers it took some time to realize exactly how the different look and feel of the film would translate into the finished print. There are those that say there is no difference between different film developers. They may also say there is no difference in the film you choose. That is like saying there is no difference between Ford and Chevy; no difference between red or white wine. Maybe for some this may be the case. But for those that take the time to really look and absorb the image, there is always a difference. Fred Picker said, “different is not the same!” Over the past 20 or so years Pyro film developers have again become popular, with modern reformulations for modern film. John Wimberley, Gordon Hutchings, Sandy King, Jay DeFehr, among others, have done a lot of research and have formulated numerous reincarnations of Pyro film developers, specifically designed for use with modern film. Steve Sherman, Bob Herbst, Michael A. Smith and Steve Simmons have written extensively about Pyro developers and their unique qualities. Susan and I have made our choice based on our own real world experiences. We join with the many others that are also Pyro developer users.

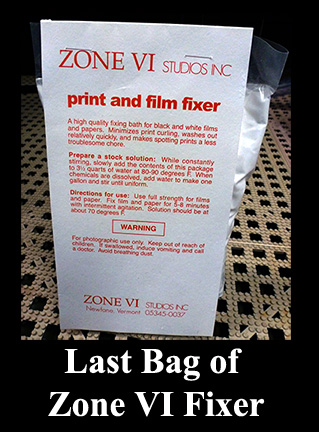

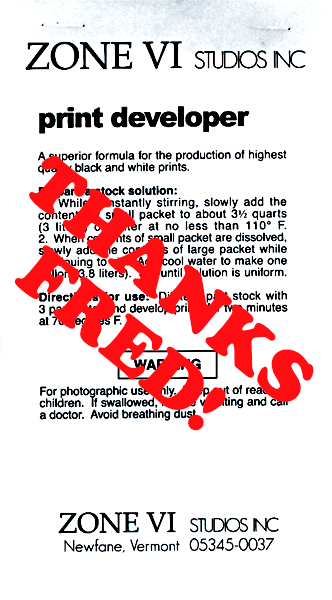

Over the past 20 or so years Pyro film developers have again become popular, with modern reformulations for modern film. John Wimberley, Gordon Hutchings, Sandy King, Jay DeFehr, among others, have done a lot of research and have formulated numerous reincarnations of Pyro film developers, specifically designed for use with modern film. Steve Sherman, Bob Herbst, Michael A. Smith and Steve Simmons have written extensively about Pyro developers and their unique qualities. Susan and I have made our choice based on our own real world experiences. We join with the many others that are also Pyro developer users. It has finally happened! I have used Zone VI chemicals for well over twenty five years now. Though we have moved on to different formulations for finished prints, we have continued to use Zone VI Print Developer for proofing. That is. . . until now. I mixed the last bag for proofing our 2015/2016 trip and that is that. This has been a looming change that has been in the back of my mind for several years now and it finally came time to do some testing. OH Drat. . . TESTING!!!

It has finally happened! I have used Zone VI chemicals for well over twenty five years now. Though we have moved on to different formulations for finished prints, we have continued to use Zone VI Print Developer for proofing. That is. . . until now. I mixed the last bag for proofing our 2015/2016 trip and that is that. This has been a looming change that has been in the back of my mind for several years now and it finally came time to do some testing. OH Drat. . . TESTING!!!

We have just updated the FORMULAS area here on the jbhphoto.com BLOG (click the link at top of the page). What you will see is mostly cosmetic with a few corrections here and there. The formatting of the older area was made of screen grabs of notes and was not that well organized. Hopefully it is now a little more tidy.

We have just updated the FORMULAS area here on the jbhphoto.com BLOG (click the link at top of the page). What you will see is mostly cosmetic with a few corrections here and there. The formatting of the older area was made of screen grabs of notes and was not that well organized. Hopefully it is now a little more tidy.